AS 90

Intermittent motion horizontal cartoner, entirely made with balcony construction, designed around three basic concepts: versatility, ergonomics and maximum efficiency in a small footprint. Because of its characteristics it is the ideal solution for packaging Pharmaceutical and Cosmetic Products. Due to its intermittent motion, it’s indicated for some specific product types.

- Balcony construction, as per GMP rules;

- Compact Dimensions;

- Maximum visibility for the whole process, thanks to completely transparent guards;

- Bucket feeding chain into which, by means of dedicated feeders, the products are placed automatically to be cartoned. One sensor checks product presence in the bucket and calls the correspondent carton and leaflet (if necessary), enabling the sensors of correct retrieval.

- All feeding groups are located in ergonomic position, in order to make the loading easy for the operator;

- Carton Pick-up and Positive Opening mechanism consists of a tilting arm combined with a mechanical Pre-Breaking device that places the erected carton directly into the carton transport belts, which guarantees optimal operations with the widest range of cartons and cardboard quality;

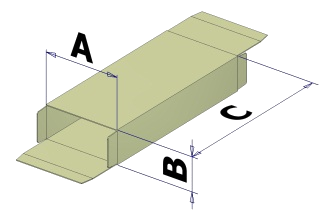

- Carton transport with Bottom timing belts centrally adjustable with hand wheels and digital indicators to suit carton Width, Length and Depth (“A”,”B” and “C” dimension);

- Particularly low noise and Lubrication free thanks to advanced solutions adopted for product and carton conveyors

- Product arriving from the infeed chain is inserted with a pusher placed on the operator side;

- After the closing operation, lateral belts discharge the carton;

- Touch screen control panel, for operator interface and machine management;

- Self-diagnosis and help functions;

- The carton transport system consists of scratch-proof white plastic toothed belts to insure package integrity, even when processing cartons with a high gloss finish. The AS150 cartoner is ideal for handling fragile or delicate products including cartons with internal liners.

Automatic feeding systems tailored according to specific requests.

Leaflets variants (pre-folded, flat, from reel).

Booklet and object insertion.

Automatic reject of incomplete cartons.

Automatic size changeover adjustments.

Possibility to integrate bar code readers and complete vision system for detection of products quantity, printed code and leaflet presence.

Wide selections of coding systems (embossing, ink-jet, laser etc.).

Variants of cartons closure (tuck-in flaps, glue flaps, tamper-evident etc.).

Variants of cartons style (cartons with inner partition, cartons with 5th panel, cartons with hinged lid, sleeve etc.).

Separate double discharge.

Modem for trouble shooting.

Validation documents (IQ, OQ e FAT) supplied according to the customer’s request.

Connection to host computer.

- Size range

- A = min. 15 mm – MAX. 120 mm

- B = min. 10 mm – MAX. 70 mm

- C = min. 70 mm – MAX. 200 mm

- Size changeover = OPERATOR FRIENDLY

- Fast and reproducible adjustments through scaled spindles with hand wheel and digital indicator plus operator guidance via operating terminal

- Mechanical speed = up to 80 Cartons per minute

- Installed Power (Basic machine) = 3,5 KW

- Air consumption (Basic machine) = 17 NI per minute

- Air pressure = 5/6 bar

- Approx Net weight = 1150 KG

- Noise level = <72dB