K 15L

The K 15L automatic Side Loading case packer incorporates a new concept which makes it particularly suitable for the packaging of individual or bundled cartons into pre-glued RS cases. In particular, its essential aspects include compact design, high accessibility, simple size change-over maximum reliability, and it is the ideal solution in case of space restrictions at the end of the line.. Cases can be sealed by means of an adhesive tape and/or of hot-melt

The machine is equipped with a horizontal carton magazine for easy loading. Positive Pick-up and forced opening arms fitted with suction cups ensure that the case is maintained perfectly erected during product insertion, while the precise conveyor system ensures positive delivery of the filled case to the sealing station.

Product insertion happens by means of a mobile tunnel, to minimise all the mechanical movements in order to gain speed, reliability and lasting time.

- Cantilever design on both sides for great accessibility and easy cleaning;

- Case positive erection and loading;

- All operations are fully automated, performed by brushless motors;

- The case blank is fed into the magazine, located in an ergonomic position on the front of the machine;

- The case blank is picked up and transferred to the opening unit by double arms equipped with suction cups, holding it from back-side and bottom, and thus guaranteeing a perfect squaring;

- The products arriving from the infeed belt, are grouped, vertically stacked inside the hopper and finally pushed into the case;

- Chain conveyors transfer the case to the flap folding and taping area;

- Simultaneous adjustment of taping units depth;

- Optimal visibility during the whole packaging process;

- Automatic end-of-batch machine emptying;

- The touch screen operator interface control panel shows all the machine functions and displays the machine status, as well as fault/alarm messages;

- The speed is set from the control panel and allows the adjustment for the optimal production speed.

Automatic feeding systems tailored according to specific requests.

Case labeling and label verification.

Case rejection at discharge.

Case overturning at discharge.

Automatic size changeover adjustments.

Possibility to integrate bar code readers and complete vision system for detection of products quantity and printed code.

Case Magazine extension.

Wide selections of coding systems (Hot-Foil, ink-jet, laser etc.).

TV camera for checking that case has been properly filled.

Product tracking system.

Modem for trouble shooting.

Validation documents (IQ, OQ e FAT) supplied according to the customer’s request.

Connection to host computer.

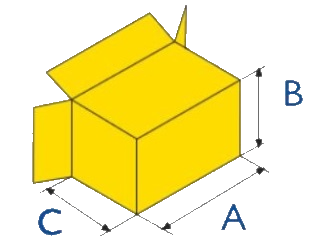

- Size range

- A = min. 140 mm – MAX. 600 mm

- B = min. 100 mm – MAX. 400 mm

- C = min. 100 mm – MAX. 450 mm

- Size changeover = OPERATOR FRIENDLY

- Fast and reproducible adjustments through scaled spindles with hand wheel and digital indicator plus operator guidance via operating terminal

- Mechanical speed = from 15 Cases per minute

- Installed Power (Basic machine) = 3,8 KW

- Air consumption (Basic machine) = 30 NI per minute

- Air pressure = 5/6 bar

- Approx Net weight = 1200 KG

- Noise level = <72dB